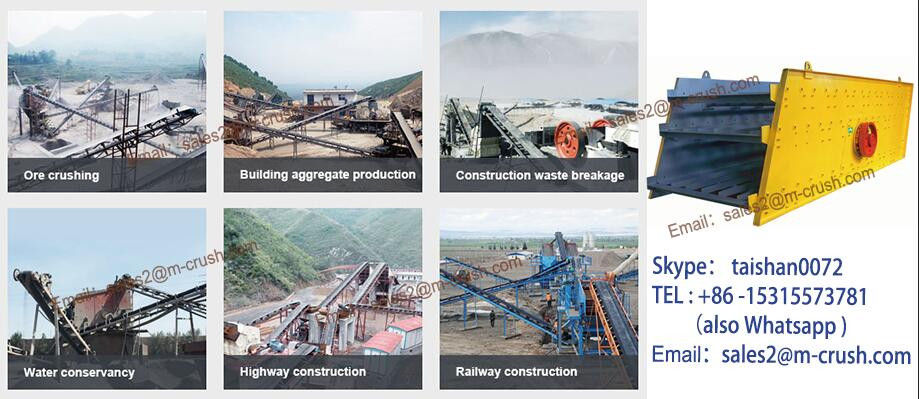

vibrating screen machine Application:

It is widely used for screening in wide range including mines, building material, transportation,

energy sources, chemical industry, etc.

Working principle of vibrating Screen machine :

The vibrating screen consists of screen box, supporting device, vibration exciter, transmission

part, etc. The barreltype vibration exciter is installed in the middle part of the machine.

During normal operation, the vibration of exciter will drive the screen mesh fixed on the screen

box vibrate, and then materials will be screened. The big and small materials fall from the

upper side and lower side of the screen to get them separated.

vibrating screen machine Advantages:

1.reliable structure,

2.2strong exciting force,

3.high screening efficiency, l

4.ow vibrating noise,

5.long durability, convenient maintenance, safe operation,

Operating Principle of vibrating screen machine:

It adjusts the amplitude by tube-shaped violent vibrating screen of eccentric shaft and eccentric blocks. The body moves in a circle in order to get the materials screened.

vibrating screen parameters

Model |

Screen Surface Layers |

Screen Size

(mm) |

Sieve Size

(mm) |

Max Feed Size (mm) |

Handling Capacity

(m3/h) |

Vibration Frequency

(r/min) |

Double Amplitude |

Motor Power (KW) |

Weight

(kg) |

Screen Surface Inclination |

Screen Surface Specification (mm) |

YK1236 |

1 |

4.3 |

1-100 |

200 |

30-160 |

970 |

8 |

5.5 |

3210 |

20o |

1200x3600 |

2YK1245 |

2 |

5.4 |

3-50 |

200 |

32-180 |

970 |

7 |

11 |

4320 |

20o |

1200x4500 |

YK1530 |

1 |

5.25 |

3-50 |

200 |

34-200 |

970 |

8 |

11 |

3355 |

20o |

1500x3000 |

YK1545 |

1 |

6.75 |

3-50 |

300 |

44-258 |

970 |

8 |

11 |

3900 |

20o |

1500x4500 |

4YK1548 |

4 |

7.2 |

3-100 |

300 |

47-275 |

730 |

8 |

18.5 |

7090 |

20o |

1500x4800 |

YK1848 |

1 |

8.8 |

3-100 |

400 |

56-330 |

755 |

11 |

15 |

7122 |

20o |

1800x4800 |

3YK1848 |

3 |

8.8 |

3-100 |

400 |

56-330 |

970 |

7 |

22 |

6935 |

20o |

1800x4800 |

YK1860 |

1 |

10.8 |

3-100 |

400 |

66-630 |

970 |

8 |

15 |

7222 |

20o |

1800x6000 |

YK2160 |

1 |

12.6 |

3-100 |

400 |

81-720 |

970 |

8 |

18.5 |

8860 |

20o |

2100x6000 |

2YK2160 |

2 |

12.6 |

3-100 |

400 |

81-720 |

970 |

8 |

30 |

9240 |

20o |

2100x6000 |

YK2460 |

1 |

14.4 |

5-150 |

400 |

150-810 |

730 |

8 |

22 |

6200 |

20o |

2400x6000 |

Mining Vibrating Screen is one of the unique product or equipment,Economic and durable quality vibrating screen machine spring is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Economic and durable quality vibrating screen machine spring is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD

Mining Vibrating Screen is one of the unique product or equipment,Economic and durable quality vibrating screen machine spring is used for separating the stuff. The circular vibrating screen work on circular motion. The vibrating screens are mainly used in coal dressing,metallurgy, mine, power station, water conservancy project, building industry, light industry, and chemical industry. Mining Vibrating Screen are efficient screening machines for the classification of bulk material such as coal, minerals, coke etc.

JHHVDGG

Economic and durable quality vibrating screen machine spring is compiled of mainframe, screen web, rub spring, electric motor, coupler and some more. It has several layers and is of high efficiency. Mining Vibrating Screen The eccentric shaft vibration exciter and partial block help to adjust amplitude. The material drops down along the long line.

JHGJHVGD