rotor diameter Smetal hammer mill,hammer crusher

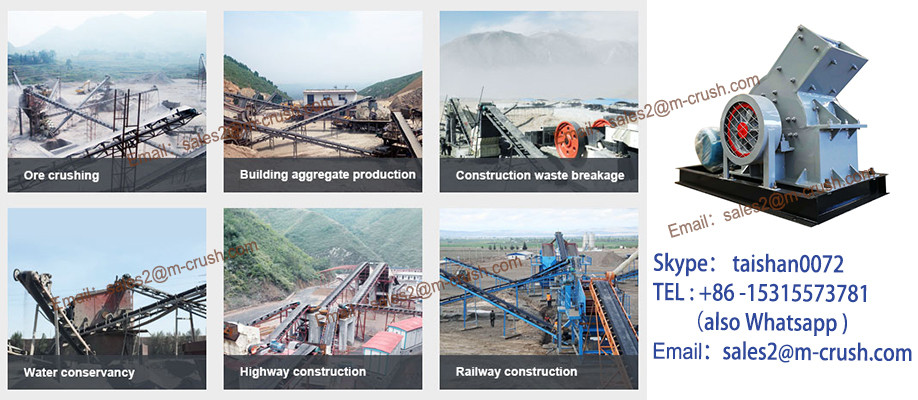

Our company has a long history of single-stage hammer crusher production. In 1980, PCY-S2020 single-stage hammer crusher produced for Guangxi Litang Cement Factory by our company, won the second prize of Liaoning Science and Technology Advance Prize. The large and medium single-stage hammer crushers produced by our company possess the characteristics of high production capability, large crushing ratio, even product size, and simple process flow and so on and have the double feeding rollers and single feeding roller function. The products have formed a series to satisfy the following requirements of 5000t/d cement production line for crushing the lime stones.

Model Number |

rotor diameter |

rotor width |

input mm |

output mm |

capacity-t/h |

Power-kw |

PCY-S1616 |

1600 |

1600 |

800 |

80 |

150 ~ 250 |

280 |

PCY-S2020 |

2000 |

2000 |

1100 |

80 |

400 ~ 600 |

630 |

PCY-S2022 |

2000 |

2200 |

1100 |

80 |

600 ~ 800 |

900 |

PCY-S2030 |

2000 |

3000 |

1500 |

80 |

1000 ~ 1200 |

1000 |

Service

Consulting

- Experienced FAM engineers provide customer-oriented consulting services worldwide for any materials handling system independent of its manufacturer

- Recommendations for efficient operation and optimization of machines and plants to reduce energy, spare parts, consumables and personnel costs

- Consulting services for increasing the availability of equipment and plants based on preventive maintenance and use of improved materials and processes

Erection

- Detailed planning of erection and Smetal hammer mill,hammer crusherstruction projects for constructional steelwork and machine building based on tried and tested erection technologies

- In-house manufacturing and erection resources

- FAM provides highly qualified, experienced, and flexible employees as supervisory personnel for erection preparation and implementation

- Direct access to highly qualified personnel

- Adhering to international safety and quality standards

- Our competent project managers guarantee that projects are implemented according to schedule

Maintenance and Repair

Service personnel is available around the clock (24/7)

Maintenance

- Preparing maintenance documentations

- Performing planned maintenance work

- Recording information on maintenance work

- Preparing planned system shutdown

- Full-time maintenance

Inspection

- Preparing inspection documentations

- Performing regular inspections

- Recording inspection work

- Giving recommendations on required maintenance work

- Identifying components that should be replaced

- Analyzing faults and availability

Repair

On request

- as a preventive measure according to schedule,

- based on operating hours or

- condition-based.

- Planning and preparing complex repair jobs independent of a system’

- s manufacturer

- Performing maintenance work in order to restore default condition

- Functional testing and putting plants into operation

- Analyzing components and assemblies for reuse

- Preparing repair documentations

Modernization

Smetal hammer mill,hammer crusherstruction

- Revamping and modifying existing plants and equipment

- Smetal hammer mill,hammer crusherstructing systems in order to guarantee operational safety and reduce operating and maintenance costs

- Installing new electrical and control systems

- Reworking machine parts and assemblies and manufacturing new ones

- Increasing the service life of machines and systems by refurbishing assemblies and components

Performance improvement

- Performing measurements and analyses

- Developing and implementing new drive concepts

- Increasing efficiency by adapting systems to changed service conditions

Automation

- Developing concepts for automatic operation of materials handling systems and equipment

- Programming specific control software

- Installing advanced control systems for automatic operation

- Installing a system for remote maintenance of control software

Training

- Designing custom-tailored training programs

- High-quality training and instruction of operators and maintenance personnel

- Providing training courses on site or at selected reference plants

- Virtual training for selected plants

Spare Parts Service

- stomer-friendly, optimized

spare parts management concepts - Recommendations for strategic

spare parts stocking - Drawing up database generated

spare parts catalogues on data carriers - Shopping cart ordering system for spare and wearing parts by email /fax

- Manufacture and delivery of spare and wearing parts for machines and equipment

- Manufacturer-independent

spare parts service - Stocking spare and wearing parts on consignment based on separate agreements

Tele-Service

Setting-up a

Tele-service system for materials handling plants and equipment

designed to collect and diagnose operating and process data

The series of Hammer Mill Crusher have the features of small volume ,light weight ,simple structure ,easy operation and maintenance ,high ratio of crushing ,too little crush , even product size ,high producing capacity .Smetal hammer mill,hammer crusher is suitable for crushing all the materials of brittle,medium hard ,and compressive strength 150 Mpa.The features include great hammerhead work ,adoption of new technology casting ,with wear and impact resistance. This solve the problems of crushing plant dust pollution and gray body leakage.

HJBJHSDG

Hammer Mill Crusher for crushing all kinds of hard and abrasive weak materials. Smetal hammer mill,hammer crusher The compressive strength of the material does not exceed 100MPa, moisture content less than 15%. Material to be broken coal, salt, chalk, gypsum, brick, limestone and so on. Also used for crushing fiber structure, Hammer Mill Crusher strong flexibility and toughness of broken wood, paper or broken asbestos cement waste to recover asbestos fibers and so on. In addition, Smetal hammer mill,hammer crusher not only used for crushing production line, sand production line, but also in mineral processing production line replacement cone crusher.

HBDHSD