Product Description

PE jaw crusher—— mini jaw crusher

ZENITH Stone production line mini jaw crusher jaw crusher series are of 6 different models, which can meet most crushing requirements in primary and secondary crushing. Flexible discharge opening setting of jaw crusher allows perfect match with relative equipments.

PE jaw crusher are widely used in metallurgy, chemical industry, building materials, electric power, transportation and other industrial sectors, which is suitable for coarse, medium and fine crushing of various ores and rocks with compression strength not more than 147~320 MPa.such as

Hard stone: granite,quartz stone, basalt, dolomite, basalt etc.

Hard ores: iron ore, copper ore, gold ore, phosphorus ore, silicon etc.

Soft stone and ores:coal, limestone,petroleum coke etc.

Technical data —— mini jaw crusher

| Model | Feed Opening (mm) | Max Feeding (mm) | Discharge Opening (mm) | Capacity (t/h) | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

| PE200×350 | 200×350 | 170 | 20-50 | 2-6 | 220 | 6-7.5 | Y160M-6/7.5 | |

| PE250×400 | 250×400 | 210 | 20-60 | 5-20 | 310 | 6-15 | Y180L-6/15 | 1450×1315×1296 |

| PE250×750 | 250×750 | 210 | 20-60 | 8-22 | 320 | 6-30 | Y225M-6/30 | |

| PE500×750 | 500×750 | 425 | 50-100 | 45-100 | 275 | 6-55 | Y280M-6/55 | 1890×1916×1870 |

| PE600×900 | 600×900 | 500 | 65-160 | 70-120 | 250 | 6-75 | Y315S-6/75 | 2520×1840×2303 |

| PE750×1060 | 750×1060 | 630 | 80-140 | 130-260 | 250 | 8-90 | Y315L1-8/90 | 2620×2302×3110 |

| PE900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 200 | 8-130 | JR127-8/130 | 3789×2826×3025 |

| PE1000×1200 | 1000×1200 | 850 | 195-265 | 230-380 | 200 | 8-130 | JR127-8/130 | 3889×2826×3025 |

| PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 220 | 8-200 | YR355M4-8/200 | 4930×3150×3700 |

Crusher working process —— mini jaw crusher

PE jaw crusher uses a motor as power. A triangle belt and pulley drives eccentric shaft through the motor pulley to make the movable jaw do reciprocating motion according to a predetermined track. The working part of the jaw crusher is two pieces of jaw plate, one is fixed on the front wall of machine body, which is called fixed jaw, the other is swing jaw, which forming a crushing chamber with the fixed jaw, move back and forth periodically. When separating, the material enters into the crushing chamber and then the particle drops out from the bottom; when they get closer, the material is crushed by the compressive force, then the final product get out from the lower outlet.

Crushing material product

feed particle size: 425-1020mm

Outlet size:20-300 mm

production capacity: 4-800T/h

Strength :147~320 MPa

application field:

Medium size crushing of ore and bulk materials in mining, metallurgy, construction, highway, railway, water conservancy and chemical industry

applicable material:

Hard stone: Marble ,granite,quartz stone, basalt, dolomite, gravel etc.

Hard ores: iron ore, copper ore, gold ore, phosphorus ore, silicon etc.

Soft stone and ores:coal, limestone,petroleum coke, clinker gypsum etc.

The production process of crusher

The moving jaw assembly is made of high quality steel casting, and the heavy eccentric shaft is processed by forging blank, which makes the jaw crusher have superior stability. Compared with other similar specifications, we use a larger and more durable eccentric shaft bearing, so that it has a higher bearing capacity, to ensure its reliability.

The world class manufacturing process, using advanced digital processing equipment components, guarantee precision of machine parts; selection of the materials of the most high-end, greatly enhances the its compressive strength, abrasion resistance, thereby greatly prolonging the service life of the machine.

Through continuous improvement and optimization, to ensure that the performance of the machine is improved, the structure of the machine can be simplified. The whole machine is more easy to operate, maintenance is more convenient, the maintenance time is greatly shortened.

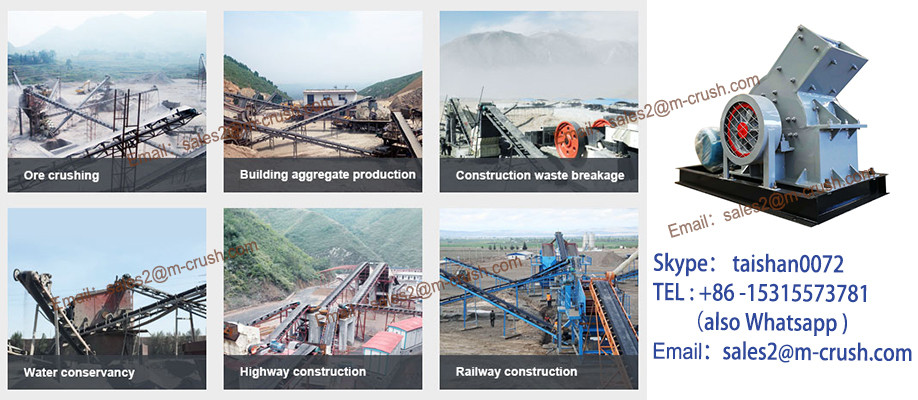

Production Line

Jaw crusher is widely used,jaw crusher in the field of mining, crushing, construction and other fields are used.The production lines are an example of the use of the jaw crushers. You can simply choose the right case for your own needs.

This is just a part of production line,As long as you leave a message,We will be based on your material, production and other information to you to configure a more comprehensive production line.

→ Basalt Stone Crushing Plant ←

→ Granite Stone Crushing Plant ←

→ Feldspar Stone Crushing Plant ←

→ River Stone Crushing Plant ←

→ Limestone Stone Crushing Plant ←

→ Cement Clinker Processing Plant ←

→ Dolomite Processing Plant ←

→ Calcite Processing Plant ←

→ Gypsum Processing Plant ←

→ Gold Processing Plant ←

→ Bauxite Crushing Plant ←

→ Copper Processing Plant ←

→ Iron Ore Processing Plant ←

Packaging & Shipping

The Bauma 2016

Shanghai ZENITH Stone production line mini jaw crusher company will attend the Bauma 2016 (the 31st Edition of the World’s ZENITH Stone production line mini jaw crusher Stone production line mini jaw crusher Trade Fair for Construction Machinery, Building Material Machines, Mining Machines, Construction Vehicles and Construction Equipment) in April, we warmly welcome you to visit our booth (Booth No.: Hall C2 Booth 122) in Bauma 2016!

Detailed exhibition information:

Location: New International Expo Center, Munich, Germany

Exhibition Booth No.: Hall C2 Booth 122

Exhibition Period: April 11-17th, 2016

Company Information

ZENITH Stone production line mini jaw crusher Stone production line mini jaw crusher is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices. Our products have been sold to 120 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.

Recent development includes the MTW series mill, vertical mill, Hydraulic impact crusher,Track mounted crusher, PEW series jaw crusher, etc. Deeply believe that the measure of our worth is in the development and innovation of new products, and we are pursuing the “ZENITH Stone production line mini jaw crusher direction of technology and quality” all the way.

ZENITH Stone production line mini jaw crusher Factory

Headquarter of ZENITH Stone production line mini jaw crusher is located in Shanghai, China and now we have two manufacturing bases as our strong support. One is located in Shanghai about 450,000 square meters, and the other is in ZENITH Stone production line mini jaw crusher Stone production line mini jaw crusher city, about 600,000 square meters. It takes about one-hour driving from Shanghai to ZENITH Stone production line mini jaw crusher Stone production line mini jaw crusher city.

Up to now, we have sales and service offices, and distributors in over 20 countries, more and more effective service will be supplied to local customers.

Our Services

ZENITH Stone production line mini jaw crusher Service

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit ZENITH Stone production line mini jaw crusher working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of ZENITH Stone production line mini jaw crusher, they are now strategically located home and abroad, working for our customers.

FAQ

Because the machines of different models, different prices, I need to ask you some details for sending you the more suitable quotation:

1.Which kind of material you are going to crush? (Dolomite; Calcite; Quartz; Basalt; Barite; Feldspar ; Gravel; Bentonite; Gypsum; Granite; Coal; Slag; Pebble; Others ) ?

2. What's the production capacity you want? How many tons or cubic meters per hour?( > 100 TPH > 50 TPH > 30 TPH > 10 TPH > 1 TPH

3.What's the granularity of the final products you need? (in milimeter, micron or mesh)

4. What's the max input size of the material? (In inch,centimeter or milimeter)

We will give you factory price with full specification,so pls leave us an inquiry to know more details about price, packaging shipping and discount.

....

The series of Hammer Mill Crusher have the features of small volume ,light weight ,simple structure ,easy operation and maintenance ,high ratio of crushing ,too little crush , even product size ,high producing capacity .ZENITH Stone production line mini jaw crusher is suitable for crushing all the materials of brittle,medium hard ,and compressive strength 150 Mpa.The features include great hammerhead work ,adoption of new technology casting ,with wear and impact resistance. This solve the problems of crushing plant dust pollution and gray body leakage.

HJBJHSDG

Hammer Mill Crusher for crushing all kinds of hard and abrasive weak materials. ZENITH Stone production line mini jaw crusher The compressive strength of the material does not exceed 100MPa, moisture content less than 15%. Material to be broken coal, salt, chalk, gypsum, brick, limestone and so on. Also used for crushing fiber structure, Hammer Mill Crusher strong flexibility and toughness of broken wood, paper or broken asbestos cement waste to recover asbestos fibers and so on. In addition, ZENITH Stone production line mini jaw crusher not only used for crushing production line, sand production line, but also in mineral processing production line replacement cone crusher.

HBDHSD