Product Description

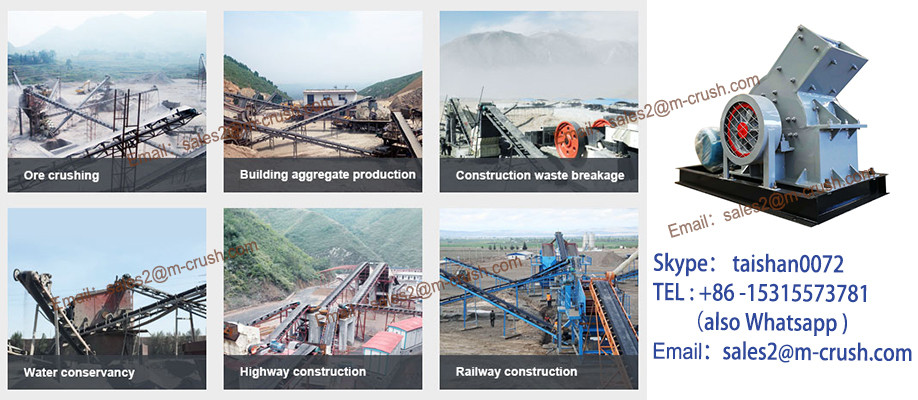

Product Application

Hammer crusher mill parts is a form of impact crushing equipment, sub-single rotor and dual rotor in two forms. It is a crushing crusher that directly crushes materials with a maximum size of 600-1800 mm to 25 or 25 mm. Hammer crusher mill parts is suitable for crushing and crushing medium-hardness materials such as limestone, slag, coke, coal and other materials in the cement, chemical, power, metallurgical and other industrial sectors.

Working Principle

Hammer crusher mill parts is mainly by impact energy to complete the crushing operation of the material. Hammer crusher mill parts is working, the motor driven rotor for high-speed rotation, the material evenly into the crusher cavity, high-speed rotary hammer impact, shear tear material caused by the material is broken, at the same time, the material's own gravity from the material from the High-speed rotation of the hammer rushed to the body baffle, sieve, larger than the mesh size of the material retained in the sieve continued hammering and grinding until the crushed to the desired size of the final discharge through the sieve plate machine.

Diesel Engine Complete Set

Hammer crusher mill parts is composed of a hammer crusher box, rotor, hammer, counterattack liner, sieve plate and other components. Mainly used in cement, chemical, electric power, metallurgy and other industrial sectors crushing medium hardness materials.

The Use of Water

The following is shown on the left, the hammer before breaking work must first add water in the diesel engine, which can play the role of heat dissipation.

Technical Parameter| Model | Feeding size (mm) |

Output size (mm) |

Capacity (t/h) |

Weight (t) |

Motor power (kw) |

Dimension(L*W*H)(mm) |

| PCφ400x300 | ≤200 | ≤25 | 5-10 | 0.8 | 11 | 900x670x860 |

| PCφ600x400 | ≤250 | ≤30 | 10-22 | 2.26 | 22 | 1200x1050x1200 |

| PCφ800x600 | ≤250 | ≤35 | 18-40 | 4.8 | 55 | 1310x1180x1310 |

| PCφ1000x800 | ≤350 | ≤35 | 25-50 | 5.9 | 75 | 1600x1390x1575 |

| PCφ1000x1000 | ≤350 | ≤35 | 30-55 |

8 | 90 | 1800x1590x1775 |

| PCφ1250x1250 | ≤350 | ≤35 | 35-65 | 14 | 132 | 2060x1600x1890 |

| PCφ1400x1400 | ≤350 | ≤35 | 50-100 | 32 | 280 | 2365x1870x2220 |

| PCφ1600x1600 | ≤350 | ≤35 | 100-150 | 37.5 | 480 | 3050x2850x2800 |

⑴ Work hammer, the use of new technology casting, with wear-resistant, impact-resistant.

⑵ According to customer requirements, adjust the required size.

⑶ Hammer broken body structure sealed to solve the dust pollution in the crushing plant and body leakage problems.

⑷ Overall design handsome in appearance, compact structure, less wearing parts, easy maintenance, etc., is upgrading products.

⑸ Compact structure, beautiful appearance, good wear resistance, easy maintenance.

Detailed Images

Machine Parts--Rotor

Rotor is the main working position of the hammer crusher, rotor by the spindle, hammer plate, pin, hammer and other components. In order to make the rotor store some kinetic energy during the movement, it is used to reduce the peak load of the motor and reduce the hammerhead wear, specially equipped with a flywheel at one end of the spindle.

Machine Parts--HammersHammer is the most important working parts. Hammer quality and material determines capacity, the size of the hammer kinetic energy is proportional to hammer weight, hammer weight can be customized, new high-quality multi-element high chromium manganese steel composite casting, the service life is several times than the general hammer.

Machine Parts--Cast Steel Grid

Hammer broken grate with high-quality cast steel, wear resistance, uniform particle size, and particle size can be customized according to customer needs.

Our Service

Pre-Sales Service

Pre-Sales Service* Inquiry and consulting support.

* Sample testing support.

* Welcome to view our Factory.

After-Sales Service* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

Company Image

Company Image Related Products

Related Products

Jaw Crusher

98.6% Response Rate

Raymond Mill

96.9% Response Rate

LK 540 Dumper

99.1% Response Rate

The series of Hammer Mill Crusher have the features of small volume ,light weight ,simple structure ,easy operation and maintenance ,high ratio of crushing ,too little crush , even product size ,high producing capacity .Pay attention to details hammer crusher mill parts,hammer mill crusher wear parts for hot selling is suitable for crushing all the materials of brittle,medium hard ,and compressive strength 150 Mpa.The features include great hammerhead work ,adoption of new technology casting ,with wear and impact resistance. This solve the problems of crushing plant dust pollution and gray body leakage.

HJBJHSDG

Hammer Mill Crusher for crushing all kinds of hard and abrasive weak materials. Pay attention to details hammer crusher mill parts,hammer mill crusher wear parts for hot selling The compressive strength of the material does not exceed 100MPa, moisture content less than 15%. Material to be broken coal, salt, chalk, gypsum, brick, limestone and so on. Also used for crushing fiber structure, Hammer Mill Crusher strong flexibility and toughness of broken wood, paper or broken asbestos cement waste to recover asbestos fibers and so on. In addition, Pay attention to details hammer crusher mill parts,hammer mill crusher wear parts for hot selling not only used for crushing production line, sand production line, but also in mineral processing production line replacement cone crusher.

HBDHSD